In July 2019, at a meeting with the President of the Russian Federation, the head of Rostec, Chemezov, requested an additional 300 billion rubles for additional capitalization of the United Aircraft Corporation (UAC). According to Chemezov, "this amount is necessary to implement the MS_21 program, as well as other civil projects in the aircraft industry." Since that time, UAC has repeatedly received additional budget allocations for the revival of the fleet of domestic airliners, the creation and mass production of which was recklessly abandoned in the mid-10s (Prime Minister Medvedev, supervising Deputy Prime Minister Dvorkovich, head of Aeroflot Savelyev). How is the situation on the main programs today? Rucriminal.info publishes excerpts from an analytical note at the request of one of the leading structures in the field of national security.

Superjet

With great difficulty, the Irkut enterprise did not fully fulfill the supply of Superjets in 2020 and 2021, despite the fact that the Government of the Russian Federation actually wrote off 60 billion rubles of problem loans and provided 100% state support with financing the leasing of 60 aircraft in Russian airlines (Aeroflot , Red Wings, Azimuth). In 2022, it is planned to produce only 10 new Superjets, which is due to the lack of a sufficient number of imported components and does not correspond to the statement of Deputy Prime Minister Manturov about the production of 20 Superjets this year.

With great delays, the creation of an import-substituting Superjet New aircraft is underway. It is expected that a flying sample of the aircraft will appear after the completion of engine certification (2024-2025). At the moment, the first sample of the PD-14 engine is being tested at the stand. Typically, in an ideal test course, the bench period alone takes at least two years, plus two years in a flying laboratory. Thus, the certification of a new aircraft with a new engine will take place no earlier than 2027, otherwise it will be possible to say that the certification of the aircraft is under a reduced program, with a large number of restrictions. Some of these restrictions, for example, resource restrictions on the Superjet aircraft, have not been lifted so far. So, due to the destruction of the wing in 2019 with an operating time of only 15,000 cycles, the service life of the aircraft is limited to this value, which is more than 2.5 times less than the design value. In practice, this means that the existing Sukhoi Superjet fleet will stop after 10 years of operation. The airframe of the new Sukhoi Superjet New aircraft completely inherited this problem, so repeated life tests of the new airframe are planned.

The capacity of the plant in Komsomolsk-on-Amur makes it possible to produce up to 40 aircraft per year, which is enough to saturate the domestic market, which is estimated at about 160-180 aircraft of this size. However, the key problem will be the supply of a sufficient number of engines and spare parts for them, manufactured by the Saturn plant, especially if there are problems with the reliability of the new hot part of the engine, as was the case with the SAM-146. The resource of the Russian version of the engine has not yet been confirmed, since key certification tests have not been completed. Repair of the hot part of the SAM-146 engine at the UEC enterprises has not yet been established, due to the lack of documentation from the French side. The situation is similar with the landing gear, APU and other key systems of the aircraft. It is possible to predict a complete shutdown of the Sukhoi Superjet aircraft fleet in terms of the exhaustion of the engine, landing gear and airframe life after 10 years of operation and 4 years in terms of engine life.

MS-21

The situation is slightly better with the MS-21 program, where the PD-14 engine has already received a type certificate and made its first flights on board the aircraft. However, here it is necessary to replace French-made electronic equipment, many American-made components and systems with Russian ones (about 50% of the cost of the aircraft), which will take at least three years. The UAC management assures that the delivery of the first 4 MS-21 aircraft is scheduled for 2023. However, to implement this task, it is necessary to build and certify the aircraft in a standard design with all Russian-made units. It will be necessary to make about 100-150 flights in various weather conditions. Thus, deliveries of the imported MC-21 aircraft can begin no earlier than in 2025, that is, 6 years later than the original plan.

The capacities for the production of the MS-21 aircraft in Irkutsk and Ulyanovsk (wing) are designed to produce 72 aircraft per year for the fifth year of production. The need for the domestic aircraft market is at least 900 aircraft. Possible export deliveries of about 200 pieces to closed markets (Cuba, Iran, Syria, Libya, North Korea). Also, there is a problem of capacities for the production of new PD-14 engines in Perm, which are now designed to produce about 10 engines per year, and the decisions made in 2021 provide a transition to the production of 50 engines per year, which is completely insufficient.. Opti The minimum output for aircraft of this type would be the production of at least 120-150 aircraft per year and 300 engines. This requires the construction of a new assembly plant, for example, in Ulyanovsk and a new engine plant in Perm or in another city where UEC enterprises are located (Ufa, Rybinsk, Kazan, Samara).

APU and other key aircraft systems. It is possible to predict a complete shutdown of the Sukhoi Superjet aircraft fleet in terms of the exhaustion of the engine, landing gear and airframe life after 10 years of operation and 4 years in terms of engine life.

IL 96-400

Despite the fact that back in 2016, decisions were made to build 6 serial aircraft of this type and one prototype, in fact, the construction of one prototype aircraft was financed, which to date is not equipped with avionics and interior. The reason is that financial resources were redistributed by the Ministry of Industry and Trade to support the Superjet program.

As a result, Russia may be left without long-haul aircraft. To reach an acceptable production capacity of 15-20 aircraft per year, a complete reconstruction of VASO with a change in equipment and aircraft production technology is required. The technology for the production of IL-96 aircraft is currently very labor-intensive (there is no robotic riveting of the fuselage and wing, an outdated fuselage stack assembly, one wing assembly station, a slip line for the general assembly of the aircraft) and allows to produce, with the available labor resources at VASO (5300 people), not more than 2-3 Il-96 aircraft per year. The demand of the Russian market for wide-body long-haul aircraft is about 100 pieces. It is advisable to consider the development of a new aircraft based on the Il 96-400M with avionics, a pilot cabin from the MS 21 and two new PD-35 engines with a thrust of 38 tons. In this case, it will be necessary to increase the capacity of the Aerocomposite plant in Ulyanovsk several times. Perhaps, at the first stage, use the existing wing, the design of the late 80s, with subsequent replacement with a new wing. The IL-96-400 aircraft with a new wing and new PD-35 engines will fully cover the needs of the domestic market for passenger and cargo transportation and can be used as a platform for military purposes. In addition, export deliveries of up to 60 pieces are possible. to closed markets (Cuba, Iran. Syria, Libya, North Korea). At the same time, work should be accelerated on the certification of the Il-96-400M aircraft, the construction of a prototype of which should be completed in 2022, significantly simplifying its avionics, unifying it with the serial Il-96-300 aircraft. It is necessary to launch a series of 10 aircraft of this type, which can be built already in the period 2025-2027. By the end of 2027, it would be possible to complete work on the creation of the Il-96 NEW aircraft with PD-35 engines. A new assembly plant for this aircraft with a capacity of 20 aircraft per year can be built either on the territory of VASO or at the Aviastar plant.

In general, the situation with the serial production of aircraft at VASO is very difficult. Due to personnel reshuffling and poor management on the part of IL PJSC, the enterprise has not produced marketable products for 5 years now, and the aircraft are not handed over to customers. The plant needs a new product for serial production, and this could be the upgraded Il-96-400 with new PD-35 engines. These aircraft are needed as a strategic reserve for transport and passenger aviation, regardless of how the Russian-Chinese CR-929 aircraft will develop.

IL-114

All program deadlines have been cancelled. Design Bureau named after S.V. Ilyushin once again in March this year. approved a new TOR for the creation of an aircraft, with a new layout, which requires processing of already issued documentation.

The main problem of the Il-114 program is the poor design of the aircraft, which leads to inefficient use of the fuselage area (64 passenger seats versus 72 for the ATP-72 and 88 for the Bombardier-Q400) with approximately equal dimensions, unreliable TV7-117ST engines, forced up to 3000 l .With. with a very small resource (only 1000 hours, versus 7000 for competitors), the impossibility of using the aircraft on unpaved airfields due to the low clearance of the propeller (40 cm), as well as the unsuccessful design of the wing mechanization, which does not allow the flaps to be fully deflected (by 40 degrees), which increases the length of the run of the aircraft on the runway. The design of the aircraft is unreliable, out of less than 20 aircraft built, two crashed.

Due to the incompleteness of the design of aircraft in the standard design, no. In the current situation, given the overload of the S.V. Ilyushin Design Bureau with other projects, it seems appropriate to consider abandoning this program and focusing on other regional aircraft that are more adapted to the requirements of the Russian market. Thus, the need for regional aircraft with a capacity of 60-100 seats for operation on concrete airfields can be covered by the Sukhoi Superjet 100 aircraft, and the need for regional aircraft with a capacity of 40-50 seats for operation at unpaved airfields can be covered by the TVRS-44 aircraft. The released financial and The personnel resources of PJSC IL can be directed to the development of the Il-96-400 long-range aircraft with PD-35 engines and the creation of a production base for it, as well as to the development of the Il-112 and Il-76 aircraft. Savings can amount to 30 billion rubles .

Tu-214 (Tu-204)

Serial production reached its peak in 2006-2008, when, by order of IFC, the Aviastar SP plant (Ulyanovsk) produced 10 Tu-204 aircraft per year. Since then, output has been falling. Since 2012, the Aviastar SP plant switched to the production of Il-76 aircraft, one of the Tu-204 aircraft assembly lines was dismantled and an Il-76 assembly line was built in its place. The second assembly line was also partially dismantled, so that the full-fledged production of Tu-204 aircraft is now impossible at this enterprise.

Over the years, the KAPO enterprise (Kazan) produced one or two Tu-214 aircraft per year for state customers on one production line. Considering that the enterprise's labor resources are limited, and the Tu-214 production technology is very labor-intensive, the probability of increasing the annual production of Tu-214 aircraft beyond 3 aircraft per year without prejudice to the main program is extremely small.

It seems appropriate to restore the airworthiness of all Tu-214s (3 aircraft) and Aviastar Tu (6 aircraft) previously produced and on the balance sheets of the IFC Tu-214 (3 aircraft) at the KAPO plant, Tu 204-100 and 204-300 (6 aircraft) at the Aviastar joint venture plant or entrust this work to UZGA Engineering. Also, it is necessary to order at least 10 new Tu-214 aircraft, which can be built in the period 2024-28. This type of aircraft can be used to transport passengers to the Far East.

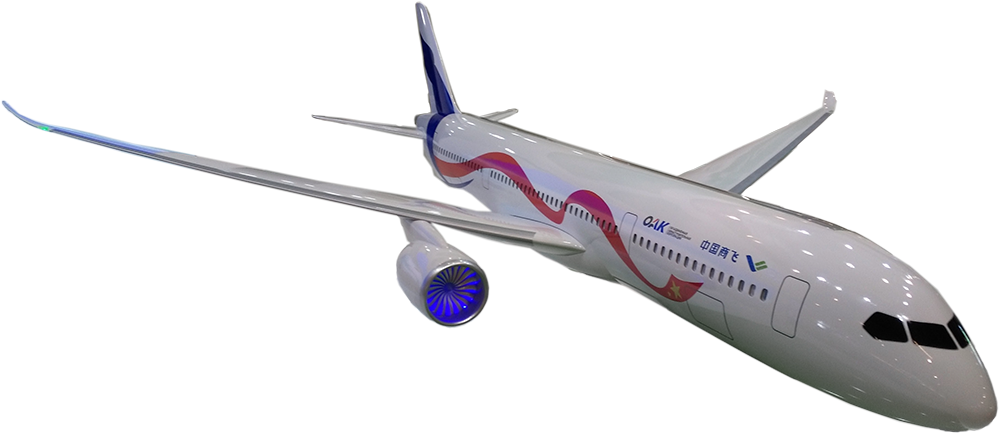

Russian-Chinese CR-929

The program is at the stage of the 4th gate (gate 4) according to Boeing's terminology: preliminary design is completed, the main suppliers of components are being selected, the detailed design of the aircraft airframe and the production of prototype aircraft are beginning. The parties have begun manufacturing the structures of the prototype aircraft, in particular, the composite-metal fuselage of the aircraft in China and the composite wing in Russia. This is perplexing for industry experts, since the selection of main suppliers, in particular engines, has not yet been finalized.

In the first phase (2022-23), it was assumed that either Rolls-Royce or General Electric engines would be used. Subsequently (2027-2030), it was planned to equip the aircraft of this family with Russian and Chinese engines, which are at an early stage of prototype testing.

In 2021, the parties managed to overcome disagreements on intellectual property issues for the aircraft and certain technologies (composite wing and fuselage), which made it possible to start building prototypes.

For serial production of aircraft, the Russian side needs to make a decision on the construction of a new plant in the Far East, near the Chinese border, since the dimensions of the aircraft wing are such that they do not allow transportation by An-124 aircraft and by rail.

Under the sanctions, the Russian side insists on the maximum use of avionics, power supply systems, hydraulics, chassis, brakes, landing gear, Russian-made interiors, analogues of which have been developed for the imported version of the MS-21 since 2018. It is also obvious that it will be proposed to use Russian and Chinese engines for this aircraft, which will automatically shift the start of flight tests of the aircraft to 2026-2027.

The Chinese side proposes to use its counterparts from the COMAC-919 aircraft, but the likelihood of this decision is small, since most of these components are produced at joint ventures between China and firms from the US and the EU.

The announced deadlines for the first flight of the aircraft in 2023 are unlikely to be met. It can be assumed, based on the stage of readiness of Russian and Chinese engines, that the first flight will take place no earlier than 2026.

To be continued

Timofey Zabiyakin

Source: www.rucriminal.info